|

Integrated Steam Path

Repairs

Valve & Governor

Inspection & Repairs

MSV Bypass Valve

Upgrades

Parts Manufacturing

|

Governors and valves are components that

usually require repair or replacement at more frequent intervals than

planned, major outages. REGENCO takes great pride in making sure our

workscope is completed within your outage window. Valve Repair and

Upgrade Programs:

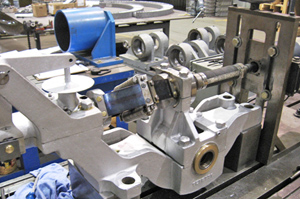

- Disassembly and inspection in a controlled shop environment

- Complete blast cleaning & NDE of valve components recommendations

- Reverse engineering & manufacture of replacement parts

- Re-establishment of appropriate clearances and restoration of internal

alignment

- Engineering evaluation of valve condition and repair

- On-site valve seat and sleeve repair

- New valve chests to replace those beyond repair

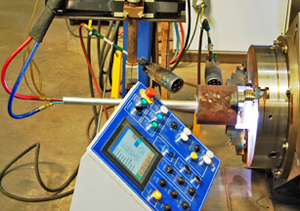

- Stellite overlay via Plasma Transfer Arc (PTA) welding

- Technical direction & on-site field machining

See MSV Bypass Valve Upgrades for additional information on bypass valve

upgrades.

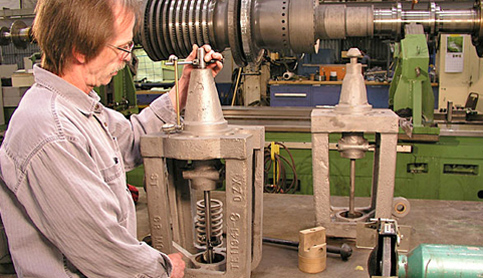

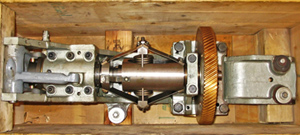

Governor Repair & Refurbishment:

We will inspect your governor, detecting potential issues, so that

corrective actions are taken before problems occur. All linkages and

bushings will be examined closely. When inconsistencies are found, our

engineering team will evaluate the situation and recommend the best course

of action.

When necessary, we will design and manufacture replacement parts to bring

the equipment back into design tolerances |

![]()