![]()

[Safety] [Quality Assurance]

[Inside Regenco]

archive copied from [http://regenco.mgi-servilink.net]

link

back to Tasker's Web Notes for Toshiba's PSD [West

Allis] Facility

|

|

|

|

|

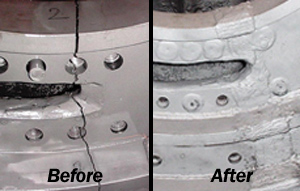

Critical steam path

|

| We offer an industry-leading array of

specialized steam path component repairs, including valves, steam chests,

diaphragms, nozzle boxes, steam path welding, stress relief and seal

replacements. These capabilities are further augmented with reverse

engineering and full turbine parts manufacturing capabilities. Turbine casing weld repairs can save you time and money… Severely cracked turbine casings, especially in older operating machines, can be repaired and returned to service. We have in-house metallurgists to formulate the best repair solution. These engineers team with certified craftsmen performing qualified procedures for welding, NDE and heat treatment. Our turbine design engineers are experienced with permanent turbine casing weld repairs. These repairs include improving horizontal joint contact and improved roundness. |