|

Condition Assessment

Failure & Fatigue

Analysis

Reverse Engineering

Dynamic Engineering

Non-destructive

Examination (NDE)

|

While many equipment repair companies need to

contract with outside vendors for engineering support, REGENCO is capable of

supplying fully integrated turbine/generator solutions. With this broad

range of engineering background, we are pleased to offer:

- Material testing for mechanical properties, including fatigue and

fracture toughness

- Failure analysis of rotors, blades and casings

- Condition assessments of turbine and generator rotors, as well as

positive material identification

- Turbine and generator component designs, including upgrades

- Reverse engineering of turbine and generator components

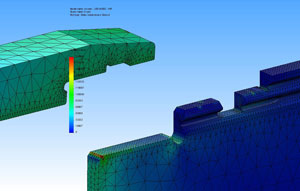

- Finite element analysis and SolidWorks computer modeling

- Material testing for chemical properties, including on-site testing

- Analysis of equipment and operational recommendations

- Technical direction and on-site repair recommendations

- Control of all on-site outage activities, including coordination of

outage shifts and work planning, coordination of on-site subcontractors

and final outage activity reports and documentation

|

![]()