|

Integrated Steam Path

Repairs

Valve & Governor

Inspection & Repairs

MSV Bypass Valve

Upgrades

Parts Manufacturing

|

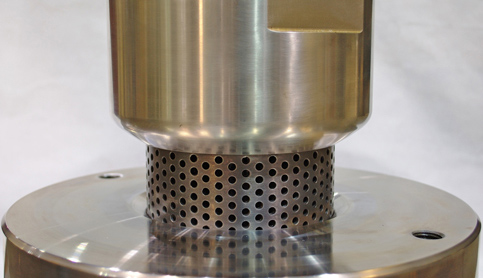

Redirecting steam improves performance over

conventional design… Conventional MSV bypass valves are configured in

such a way that steam is forced to change direction via a solid-surface

impact. This makes these valves highly susceptible to SPE and steam cutting.

REGENCO’s improved design redirects the steam path to prevent solid surface

impact, thereby eliminating erosion problems. Stellite coatings in high-wear

areas, as well as upgraded valve stem and bushing materials, also ensure

worry-free performance

- Installations range from recent replacements to many dating back more

than 20 years

- Hundreds of multi-hole valves are providing trouble-free service in

Toshiba’s OEM fleet and others

- Fleet average starts on bypass are in excess of 350 times

- Greatest number of starts on bypass—over 1,200

|

![]()