![]()

[Safety] [Quality Assurance]

[Inside Regenco]

archive copied from [http://regenco.mgi-servilink.net]

link

back to Tasker's Web Notes for Toshiba's PSD [West

Allis] Facility

|

|

|

|

|

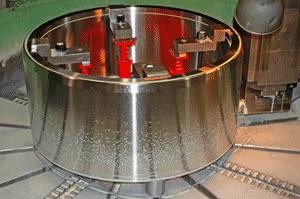

Retaining Rings—in stock

|

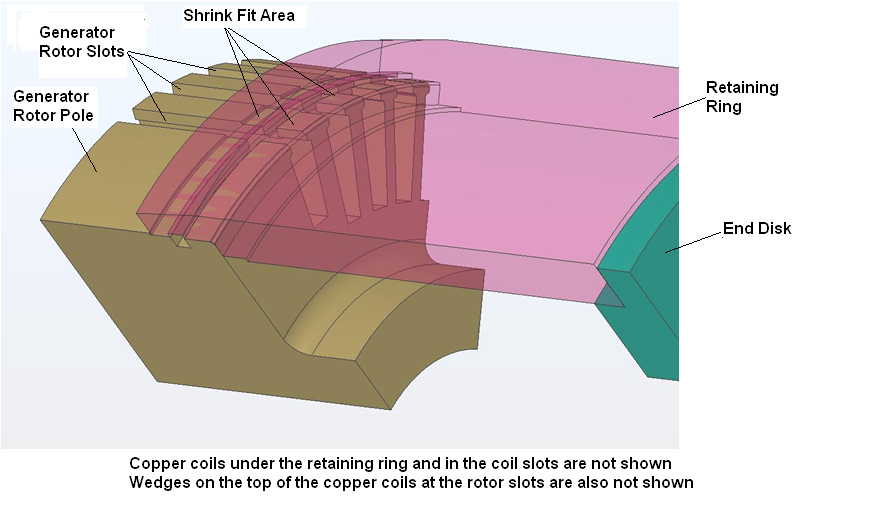

| Why wait on long forging lead times? Retaining rings are the most critical component of the generator rotor and under normal operating conditions they are the most highly stressed rotor component. Retaining rings are critical in the sense that their mechanical failure always has catastrophic consequences on the physical integrity of the machine. As such, retaining rings require the utmost attention during inspection and maintenance. Periodic inspections include visual and NDE methods, such as eddy-current, ultrasonic and dye-penetrant. Special care should also be taken with older, 18Mn-5Cr rings, especially those in environments where moisture penetration is possible. Other known problem areas for retaining rings include:

Retaining Ring “Fit” Diagram |