![]()

[Safety] [Quality Assurance]

[Inside Regenco]

archive copied from [http://regenco.mgi-servilink.net]

link

back to Tasker's Web Notes for Toshiba's PSD [West

Allis] Facility

|

|

|

|

|

The safe and sure way,

|

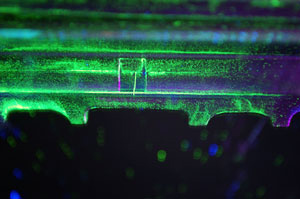

| PT, MT and ET are used to detect surface or

near surface defects, the most undesirable being of a linear nature, which

could be evidence of cracks in a component. UT is used for detection of

subsurface (including inside surfaces when these surfaces are not accessible

for other inspection methods) flaws in forgings, weldments and other

components. PMI is used in conjunction with other tests for reverse engineering purposes. This is typically deployed when parts are found to be defective, usually as a result of other NDE, or they have served their useful life. PMI uses X-ray fluorescence to nondestructively examine metal components for their make-up. PMI testing only takes a few seconds in most cases. In addition, industrial X-ray inspection services are available to REGENCO locally and have been used for in-house inspections, as well as for welding certifications. Inspectors who must perform NDE inspections at REGENCO are highly trained and are tested at required intervals per ASNT TC-1A. Level III inspectors conduct required testing for all of our NDE inspectors. |

|

|

|

|